About

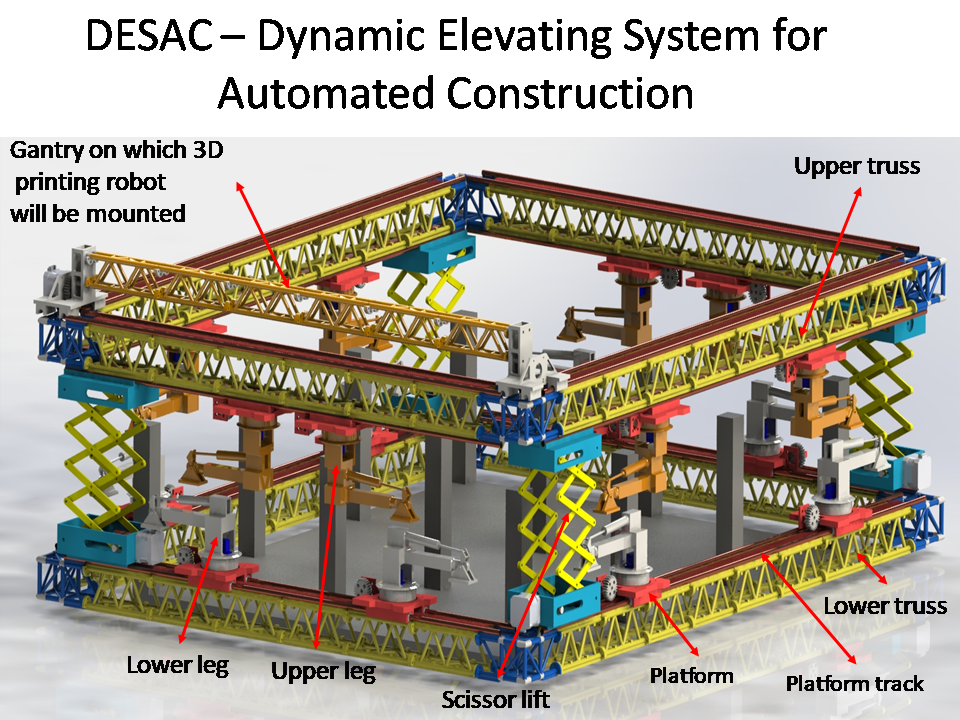

Focused and enthusiastic mechanical engineer with a keen interest in product research & development, simulations, rapid prototyping and product lineup. By comprehensive exposure to the underlying concepts and applying them vividly to various projects, my love for these domains came into being. I am a passionate individual who thrives to build a product to solve real-world industry problems.

- Birthday: 04 Feb

- Phone: +91 8840757242

- Location:Earth, Solar System, Orion Arm-Milky Way, Universe

- Email: hkhan.robotics@gmail.com

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

(1).png)

.png)

.jpg)

.jpg)